Placement of Specialize LED components Solved!

Don't miss our assembly video at the bottom of the page!

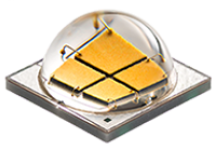

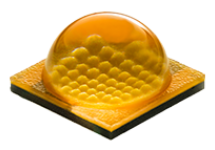

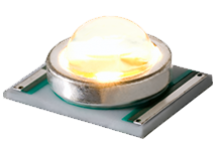

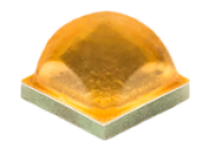

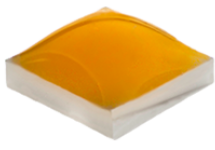

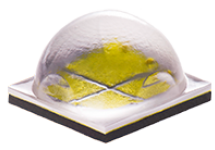

Many flat LEDs, like the J Series LEDs from Cree®, can be assembled much like any other comparable surface mount device. But when you begin to utilize domed LEDs like the Cree XLamp series, or Lumileds Luxeon T, Luxeon SunPlus, or UV components, the process of placement becomes more difficult. These more challenging components require a unique approach. The installation of these chips is more of an art form.

Much like the design phase of LED lighting products, where engineers have to consider all the variables. i.e., How and where will the product will be used? What type of fixture is required? How bright (lumens), what color (CRI - Color Rendering Index), will it need dimming or color tuning capabilities, how will it be powered, cooled …? It is not a simple process, but when done well, you have an incredibly useful product.

Placing specialized components requires a similar approach. If you hope to reach acceptable levels of production and efficient use of materials, you have to rethink what you thought you knew about placing surface mount devices. You will need to make adjustments to every phase of the assembly process. It may even require some re-engineering to get the board and its' parts ready for the fast lane. Knowledge of these adjustments only comes with experience, and each uniquely designed LED will require its' solution. Some engineers avoid using these more challenging LEDs because their manufacturing capabilities lack the necessary expertise to assemble the boards successfully.

When manufacturers tackle these challenging LEDs for the first time, they should expect some problems resulting in;

- Unacceptable component waste

- Poor picking stats

- Poor placement stats

- Too many damaged LEDs

- Unacceptable first-pass yield stats

- Unacceptable levels of rework, replacing damaged LEDs, adding missing LEDs, or removing and replacing

- Additional labor costs to remove solder beads

These issues are real, and many OEMs find it very frustrating, and they begin a trial and error approach to manufacturing, which is not what any of us want. And most contract manufacturers run into the same roadblocks, so they are forced to raise their pricing for these projects or avoid them altogether.

How We Can Help

Here at Global, we developed specific manufacturing techniques for these unique LED components. Our processes allow us to manufacture these boards with the same high-efficiency and speed demanded in electronics manufacturing, resulting in faster turn-around times and costs savings.

We have procedures in place to run more than 5,500 unique LED part numbers, and we have placed millions of each. Please visit our Custom LED Assembly page to view a list of the challenging LEDs we use regularly. For more information on a specific part, feel free to email us at RFQ@gmsww.com and allow us to review the specifications for the component, and provide feedback regarding our knowledge and experience working with it.